Products

Vibration Analyzer Balancer

Predictive maintenance tools for vibration analysis help prevent machine failures and costly production downtime.

Features

Introduction

In recent times, many industries have been experiencing an increase in the need for machinery and equipment maintenance. One significant aspect of machine maintenance is its balancing process. Machine balancing is very critical in ensuring that the equipment operates efficiently and effectively. Balancing enhances machine reliability, which in turn improves the overall productivity of the industry. In response to these needs, my company has developed a Vibration Analyzer Balancer that is efficient, reliable, and durable. The Vibrations Analyzer Balancer is designed to help businesses avoid unexpected machine downtime, reduce maintenance costs, and extend the operating life of their machinery.

Features of the Vibration Analyzer Balancer

The Vibration Analyzer Balancer is a piece of high-tech equipment that measures machine vibration and provides tools for dynamic balancing. This device can automatically balance mechanical rotating and reciprocating equipment without the need for manual dynamic balancing. It is a compact portable device made using high-quality materials making it a durable product.

Measure Vibration

The Vibration Analyzer Balancer has an advanced dual-channel high-resolution measurement system that can measure both vertical and horizontal vibrations accurately. It can measure a range of machine vibrations from 0.001 mm/s to 199.9 mm/s with an accuracy of up to 5%. This high accuracy is critical in identifying potential machine problems early, allowing for corrective action to take place before the failure of the machine.

Dynamic Balancing

The Vibration Analyzer Balancer relies on advanced algorithms to obtain accurate measurements of vibration and work towards the identification of potential balance issues. Through this analysis, the device provides relevant information on weight correction, providing a balance solution for the machine. The device has a powerful analysis capability that provides information on balancing position, weight requirement, and corrective action required.

User-friendly

The Vibration Analyzer Balancer is easy to use - it has a user-friendly interface that can assist both experts and beginners. The device comes with a large color screen display, which provides clear and easy-to-read data feedback. The device is equipped with a function menu that guides the user on the operations involved in the measurement and dynamic balancing process.

Furthermore, it has a wide range of balancing parameters that can meet the different types of machinery that clients may have. The user can easily input specific limited parameters provided by the device to assist in the balancing process. Therefore, this device can assist the user minimize machine downtime and improve production efficiency.

Advanced alarm settings

The Vibration Analyzer Balancer has an advanced alarm setting that alerts operators if there is an issue with the machinery. This feature ensures that machine operators can take corrective action before the machine malfunctions, set alarms for unusual vibration levels, and unexpected changes in dynamic balancing. This feature can save users money and time since the machine will not undergo unexpected breakdowns.

Durability

The Vibration Analyzer Balancer's high-quality material ensures that it can withstand harsh working conditions, last long and perform better. It provides durability, reduces the need for regular replacements, making it a cost-effective device.

Ease of Ownership

The purchase of the Vibration Analyzer Balancer includes a comprehensive user manual outlining how a user can properly use the device. Our company also provides professional technical support, including training on the device's use, installation, and maintenance. The customer care team is available 24/7 to answer customer concerns.

Conclusion

In conclusion, the Vibration Analyzer Balancer is a necessary tool for businesses to keep their machinery operating smoothly. It will assist clients in reducing maintenance costs, prolonging machine life, and increasing production efficiency. The Vibration Analyzer Balancer ensures that users have access to precise data and tools to dynamically balance their equipment without needing heavy manual labour. With our focus on durability, ease of ownership, advanced alarm settings, and user-friendly, our product is a smart choice for clients. Contact us today to learn more about the Vibration Analyzer Balancer and how it can meet your machinery needs.

KMbalancer®II

Vibration Analyzer balancer

Predictive maintenance tools for vibration analysis help prevent machine failures and costly production downtime.

Our vibration analysis tools are used for condition monitoring of rotating equipment to help detect early component wear and damage. Vibration analysis and balancing is an integral part of any condition based and predictive maintenance plan.

One and two plane field balancing & vibration analysis,Portable all-in-one system for effective vibration monitoring.Field balancing fast and accurate.

Imbalances on rotating drive shafts can be detected and eliminated with the KMbalancerII.

The smart measuring principle and the powerful computing capacity enable balancing on one or two planes. Various operating modes are available for balancing, so that a perfect result is always achieved.

Why we need KMbalancer®II

PdM & CBM

PdM(Predictive Maintenance)and CBM(Condition Based Maintenance)is the trend of modern industrial maintenance strategy. It`s the only way to equipment maintenanceto change PdM(Predictive Maintenance)and CBM(Condition Based Maintenance)is the trend of modern industrial maintenance strategy. It`s the only way to change the equipment maintenance from spend money to make money.

On the basis of the condition of the machine, PdMand CBM will decide that whether the machine should be maintained. For example, we use the technology of vibration detection to analyze the abnormal cause of machine, extent of damage and life prediction. So we know when and where to repair the machine? In this way, we can reduce maintenance costs, increase production capacity and improve enterprise's competitiveness.

CONDITION

KMbalancer®II are suitable for all kinds of rotating machines, such asmotor, pump, air compressor, windmill, gear box, steam turbines, generators, cooling towers, etc.With the powerful KMVS Pro Data Collection and Analysis software, we can managethe equipment database, monitortrend of state, analyze the abnormal cause and output the report, etc. Its spectrum analysis and time waveform analysiscan be used as the basis of the condition monitoring.Generally speaking, forthe equipment maintenance personnel, the bearing condition of rotating equipment is the most concerned problem, KMbalancer®IIhas powerful data processing ability with 400MHz high-performance embedded microcontroller processor.With the built-in bearing fault database , KMVS Pro can be used to analyse early abnormal problems of the bearings.

SOLUTION

KMbalancer®II is easy and practical to operate.Most of the high order vibration analyzer has a problem that the function of measurement analysis is set too cumbersome,which is not suitable for maintenance detection and improve problems in the factory.KMbalancer®IIcan analyze all kinds of vibration problems, such as imbalance, misalignment, shaft bending, loose of equipment, fluid turbulence, poor lubrication, abnormal conditionof motor、bearing and gear, etc.

CORRECTION

In the problems of rotating mechanical damage, there are 40% ~ 50% to be associated with poor dynamic balance. The problem of dynamic balance not only consumes power, but also easily causes the wear and tear of bearing, mechanical shaft seal and shaft components.Besides vibration analysis, KMbalancer®II also can do the dynamitic balance adjustment. It can undertake single or double plane dynamic balancing correction from equipment of 60 ~ 300000 RPM.

Who is using KMbalancer®II

Petrochemical Industry Petrochemical industry is responsible for the production of hydrocarbon fuel, lubricating oil and so on to meet the global demand for energy.In order to meet the production requirements, the machines with requirements for operation standards are put into use. Once downtime, the damage will be enormous. KMbalancer®II can be applied to key equipment in factory, such aspumps, compressors, ventilation equipment, exhaust fan and power equipment. |  |

Machine Building Industry Machine building industry provides technical equipmentsfor industry, agriculture, transportation, national defense, etc. It is the base of the national economy and defense modernization technology. As a result, the development of the Machine building industry is the measure of the lever of economic development and science and technology of a country.KMbalancer®II can be applied to equipment monitoring and improvement for the manufacturer, such asdynamitic balance adjustment on the spindle of CNC manufacturing, the vibration monitoring and the balance of fan manufacturing other kinds of power equipment. |  |

Colleges andScientific Research Units As the base of training technical talents, colleges and universities and scientific research units have always been taken the theory of technology research into practice. On the premise of consolidated theory knowledge, it constantly introduces advanced equipment for practical operationand providesguaranteeof cutting-edge technology for the country. KMbalancer®II has gainrecognition from numerous colleges and universities and scientific research units. It is well applied to the mechanical lab |  |

Power Industry As the mass production of power, the structure of the power equipment become more and more complex, and the relation between each subsystem become closer and closer. Once any part of the equipment has a failure in the process of operation, it will be likely to interrupt production, which will cause huge economic losses.In order to ensure the operation of power system safety, economic and stable, fault diagnosis of power equipment will be turned tothe form of state monitoring.In order to optimize the equipment management and preventive monitoring, the devices are usually divided into two categories: steam turbine generator and accessory equipment.Windpower :generator, gear box, bearing of main shaftThermal power: ventilation equipment, turbine, steam turbine, generator, condensate pump, circulating pump and auxiliary pump |  |

Iron and Steel Industry With the sustained growth of steel demand around the world, the competition of metallurgy and non-ferrous metal industry is increasingly fierce. How to improve the competitiveness of enterprises and reduce the cost of finished steel, vibration monitoring of the equipment is the best andthe most effective way to implementit . KMbalancer®II can be applied to following plants: coking plant, blast furnace, smelting, basic oxygen furnace (BOF), open hearth furnace, hot-rolled and cold-rolled plant. KMbalancer®II can mainly be applied to the following equipment: motor, all kinds of fan (drum/induced draft fan, sintering fan, one/two dust removal fan, etc.), instr air compressor, rolling mill, coiling machine, casting machine, the gearbox, crane, pump and ball mill. |  |

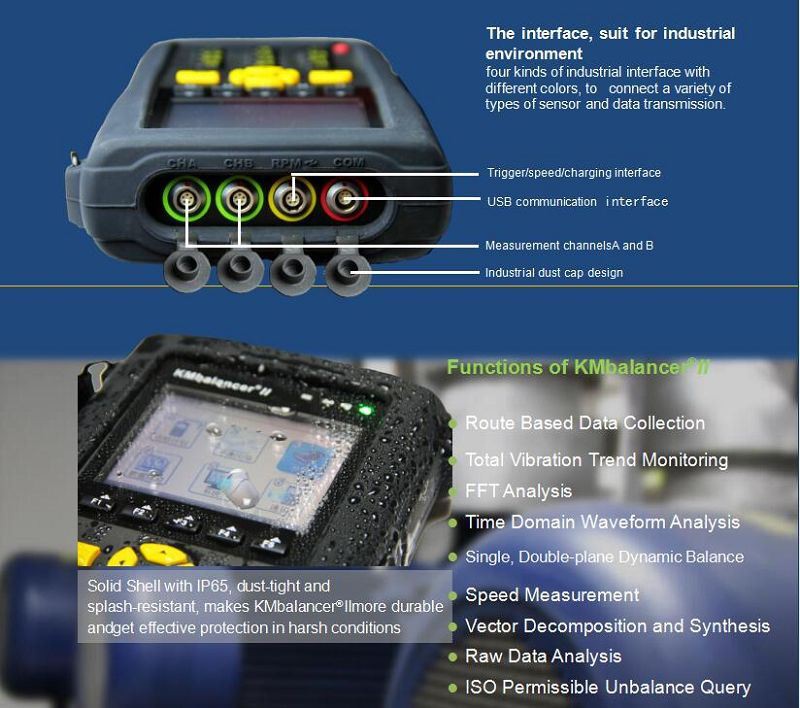

Features of KMbalancer®II

Features of KMbalancer®II

KMVS Pro Data Collection and Analysis Software

KMbalancer®IIComplete Kit

Specifications of KMbalancer®II

Display:Colorful backlit LCD screen, 320*240pixels, TFT 65536

Storage:

RAM64M

Flash1GB

Communication:USB2.0 Full Speed

Power:Lithium-ion, Operating time >8 hours continuous, Recharge time 2-3 hours

Size:190 x 110 x 38mm

Weigh:900g

Conditions

Enclosure:IP65 Dust-tight and splash-resistant

Drop test:1.2m

Operation temperature:-10℃~ 50℃

Humidity range:0% ~ 80% Relative humidity

Collection

Channel2 vibration +1speed

Signal typesSpeed, acceleration, displacement, AC/DC voltage, AC/DC current

Simulation of couplingAC/DC/ICP(20V@2.4mA)

Signal:±25V

Dynamic range:>80dB

FFTresolution400~12800 lines

Analog filter:High(2Hz / 10Hz / 100Hz / 1000Hz)、Low(10Hz / 100Hz / 1000Hz / 40kHz)

Anti aliasing filter:50~40kHz

Window function type:rectangular、Hanning、Hamming、Flat Top

Lines:Linear, peak, square root

Dynamic balance

Speed range:60~300,000RPM

Dynamic balanceSingle, double-sided dynamic balance, vibration analysis, rapid dynamic balance analysis

Acquisition signal typeThe unit can be set free

Operation:Wizard type operation

Toolboxtime/frequency domain analysis, history browsing, manually entered, data review, vector decomposition/synthetic, ISO permissible unbalance query, add calculation

Why choose us?

- We provide clear and detailed product specifications to ensure product compatibility.

- The experienced engineer team provides qualified designs; the sales team provides timely and thoughtful quotations and answers according to your actual needs; well-trained production personnel and management personnel will be the basic support.

- We are always looking for ways to improve our products and services.

- Our dedication to technical excellence, coupled with strict management, ensure that our products can meet customer needs.

- Our products are CE and RoHS certified, ensuring the highest level of safety and quality.

- We implement our responsibilities with meticulous requirements, touch customers with subtle service, strive for perfection with meticulous work, pay attention to details and constantly improve.

- We have a commitment to customer satisfaction and excellence in everything we do.

- The company adopts the industry’s advanced Vibration Analyzer Balancer production equipment and professional technical personnel. Every process of Vibration Analyzer Balancer production has been strictly controlled, with professional quality and perfect after-sales The service is trusted by users.

- Our Portable Balancer products are designed to be easy to use and maintain.

- We fully mobilize the enthusiasm, initiative and creativity of our employees through effective concept guidance.

You Might Also Like

Send Inquiry