Products

Portable Dynamic Balancer

Compact and durable, large color graphic display, multilingual and ergonomic KMbalancer Portable Balancer is the simplest and fastest portable balancing device on the market.

Features

Introduction:

The Portable Dynamic Balancer is one of our flagship products that we are proud to offer, and we are excited to introduce it to our valued merchants. This product is perfect for businesses looking to reduce dynamic imbalance, which can cause machine vibration and ultimately impact performance. The Portable Dynamic Balancer is a powerful tool that can accurately detect and correct any imbalance in machinery, extending the lifespan of machine parts and reducing costly downtime.

Features and Benefits:

One of the main features of the Portable Dynamic Balancer is its portability. It is lightweight, compact, and easy to move, which makes it ideal for on-site work where it is necessary to balance machinery such as motors, fans, pumps, or other rotating equipment. The Portable Dynamic Balancer can work with loads up to 300 kg and can balance machinery at speeds between 300 and 10,000 rpm. The device is equipped with built-in sensors that measure the vibration of the machine, and the system automatically adjusts to the optimal speed for measuring and correcting the imbalance.

Another key feature of the Portable Dynamic Balancer is its easy-to-use interface. The system is designed to be user-friendly, so anyone can use it with minimal training. The operator simply needs to attach the vibration sensors to the machine, input the machine's specifications into the system, and start the balancing process. The system then provides the operator with real-time results, allowing them to make adjustments to the machine until it achieves maximum balance.

The Portable Dynamic Balancer delivers numerous benefits to its users. One of the most significant benefits is the device's ability to reduce machinery downtime. When machinery is not balanced correctly, it can create vibration, which can cause excessive wear and tear on machine parts. This can result in costly repairs and long periods of downtime. By using the Portable Dynamic Balancer to balance machinery, businesses can extend the lifespan of their equipment, reduce maintenance costs, and minimize machine downtime.

In addition to its ability to reduce downtime and maintenance costs, the Portable Dynamic Balancer also enhances overall machine efficiency. An imbalanced machine consumes more energy, which results in higher utility bills. When machines are balanced correctly, they will consume less energy, which can translate into significant cost savings. By using the Portable Dynamic Balancer, businesses can improve their overall efficiency and reduce their energy bills.

Conclusion:

Overall, the Portable Dynamic Balancer is an excellent product that offers numerous benefits to businesses across all industries. It is lightweight, portable, easy to use, and can help save businesses time and money. It will not only increase machine efficiency but also decrease downtime and maintenance costs. It has a range of features and benefits that make it an attractive option to businesses looking to reduce dynamic imbalance in their machinery. As a manufacturer, we are confident in the quality of our Portable Dynamic Balancer, and we are excited to bring this device to the international market. Contact us today to learn more about our product and to take advantage of it.

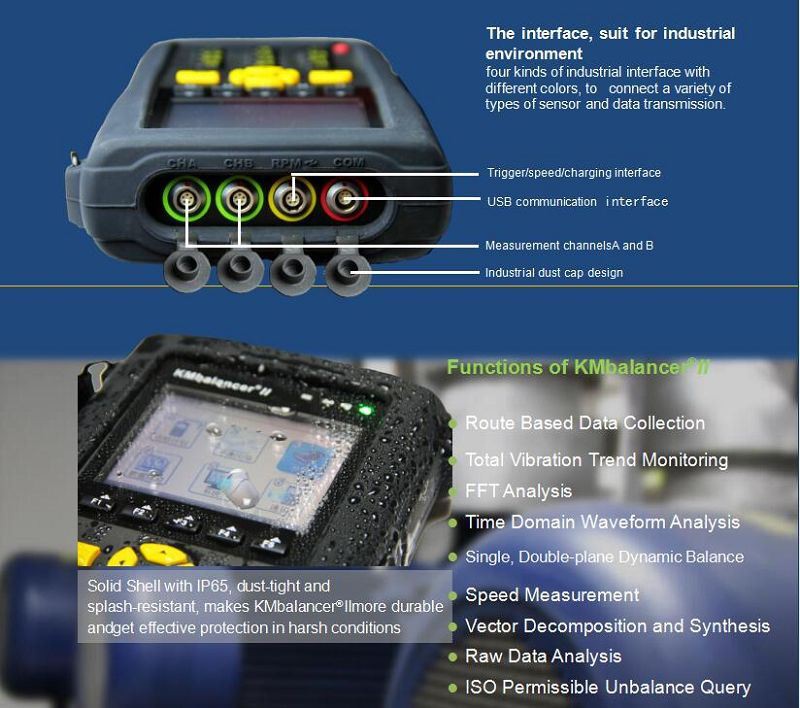

KMbalancer®II

Portable Balancer

KMbalancer Portable Balancer is an ideal solution for vibration measurement and field balance of industrial machinery.

Compact and durable, large color graphic display, multilingual and ergonomic KMbalancer Portable Balancer is the simplest and fastest portable balancing device on the market.

Fast: suitable for heavy applications, such as precision balancing machinery at the end of the assembly line.

Intuitive: ideal for occasional balancing fans or grinding wheels.

They can perform static and dynamic balancing on very large and low-speed shafts, such as the rotating tables of wind turbines and milling machines, and they are also used by spindle repair shops and CNC machine tool manufacturers.

Due to his long-term experience and highly skilled professionals, KM can provide training services at cemb facility center or customer site.

KMbalancer II is a full-function, high-efficiency dual channel FFT vibration analysis and field dynamic balance instrument. It can be used in the field of equipment condition monitoring in many industries, such as paper industry, petrochemical, power plant, machinery manufacturing and so on. Kmbalancer II can collect various field data, such as vibration value, bearing state, spectrum diagram and time domain waveform, and can further integrate and analyze equipment faults through kmvs pro data acquisition and analysis software..

Why we need KMbalancer®II

PdM & CBM

PdM(Predictive Maintenance)and CBM(Condition Based Maintenance)is the trend of modern industrial maintenance strategy. It`s the only way to equipment maintenanceto change PdM(Predictive Maintenance)and CBM(Condition Based Maintenance)is the trend of modern industrial maintenance strategy. It`s the only way to change the equipment maintenance from spend money to make money.

On the basis of the condition of the machine, PdMand CBM will decide that whether the machine should be maintained. For example, we use the technology of vibration detection to analyze the abnormal cause of machine, extent of damage and life prediction. So we know when and where to repair the machine? In this way, we can reduce maintenance costs, increase production capacity and improve enterprise's competitiveness.

CONDITION

KMbalancer®II are suitable for all kinds of rotating machines, such asmotor, pump, air compressor, windmill, gear box, steam turbines, generators, cooling towers, etc.With the powerful KMVS Pro Data Collection and Analysis software, we can managethe equipment database, monitortrend of state, analyze the abnormal cause and output the report, etc. Its spectrum analysis and time waveform analysiscan be used as the basis of the condition monitoring.Generally speaking, forthe equipment maintenance personnel, the bearing condition of rotating equipment is the most concerned problem, KMbalancer®IIhas powerful data processing ability with 400MHz high-performance embedded microcontroller processor.With the built-in bearing fault database , KMVS Pro can be used to analyse early abnormal problems of the bearings.

SOLUTION

KMbalancer®II is easy and practical to operate.Most of the high order vibration analyzer has a problem that the function of measurement analysis is set too cumbersome,which is not suitable for maintenance detection and improve problems in the factory.KMbalancer®IIcan analyze all kinds of vibration problems, such as imbalance, misalignment, shaft bending, loose of equipment, fluid turbulence, poor lubrication, abnormal conditionof motor、bearing and gear, etc.

CORRECTION

In the problems of rotating mechanical damage, there are 40% ~ 50% to be associated with poor dynamic balance. The problem of dynamic balance not only consumes power, but also easily causes the wear and tear of bearing, mechanical shaft seal and shaft components.Besides vibration analysis, KMbalancer®II also can do the dynamitic balance adjustment. It can undertake single or double plane dynamic balancing correction from equipment of 60 ~ 300000 RPM.

Who is using KMbalancer®II

Petrochemical Industry Petrochemical industry is responsible for the production of hydrocarbon fuel, lubricating oil and so on to meet the global demand for energy.In order to meet the production requirements, the machines with requirements for operation standards are put into use. Once downtime, the damage will be enormous. KMbalancer®II can be applied to key equipment in factory, such aspumps, compressors, ventilation equipment, exhaust fan and power equipment. |  |

Machine Building Industry Machine building industry provides technical equipmentsfor industry, agriculture, transportation, national defense, etc. It is the base of the national economy and defense modernization technology. As a result, the development of the Machine building industry is the measure of the lever of economic development and science and technology of a country.KMbalancer®II can be applied to equipment monitoring and improvement for the manufacturer, such asdynamitic balance adjustment on the spindle of CNC manufacturing, the vibration monitoring and the balance of fan manufacturing other kinds of power equipment. |  |

Colleges andScientific Research Units As the base of training technical talents, colleges and universities and scientific research units have always been taken the theory of technology research into practice. On the premise of consolidated theory knowledge, it constantly introduces advanced equipment for practical operationand providesguaranteeof cutting-edge technology for the country. KMbalancer®II has gainrecognition from numerous colleges and universities and scientific research units. It is well applied to the mechanical lab |  |

Power Industry As the mass production of power, the structure of the power equipment become more and more complex, and the relation between each subsystem become closer and closer. Once any part of the equipment has a failure in the process of operation, it will be likely to interrupt production, which will cause huge economic losses.In order to ensure the operation of power system safety, economic and stable, fault diagnosis of power equipment will be turned tothe form of state monitoring.In order to optimize the equipment management and preventive monitoring, the devices are usually divided into two categories: steam turbine generator and accessory equipment.Windpower :generator, gear box, bearing of main shaftThermal power: ventilation equipment, turbine, steam turbine, generator, condensate pump, circulating pump and auxiliary pump |  |

Iron and Steel Industry With the sustained growth of steel demand around the world, the competition of metallurgy and non-ferrous metal industry is increasingly fierce. How to improve the competitiveness of enterprises and reduce the cost of finished steel, vibration monitoring of the equipment is the best andthe most effective way to implementit . KMbalancer®II can be applied to following plants: coking plant, blast furnace, smelting, basic oxygen furnace (BOF), open hearth furnace, hot-rolled and cold-rolled plant. KMbalancer®II can mainly be applied to the following equipment: motor, all kinds of fan (drum/induced draft fan, sintering fan, one/two dust removal fan, etc.), instr air compressor, rolling mill, coiling machine, casting machine, the gearbox, crane, pump and ball mill. |  |

Features of KMbalancer®II

Features of KMbalancer®II

KMVS Pro Data Collection and Analysis Software

KMbalancer®IIComplete Kit

Specifications of KMbalancer®II

Display:Colorful backlit LCD screen, 320*240pixels, TFT 65536

Storage:

RAM64M

Flash1GB

Communication:USB2.0 Full Speed

Power:Lithium-ion, Operating time >8 hours continuous, Recharge time 2-3 hours

Size:190 x 110 x 38mm

Weigh:900g

Conditions

Enclosure:IP65 Dust-tight and splash-resistant

Drop test:1.2m

Operation temperature:-10℃~ 50℃

Humidity range:0% ~ 80% Relative humidity

Collection

Channel2 vibration +1speed

Signal typesSpeed, acceleration, displacement, AC/DC voltage, AC/DC current

Simulation of couplingAC/DC/ICP(20V@2.4mA)

Signal:±25V

Dynamic range:>80dB

FFTresolution400~12800 lines

Analog filter:High(2Hz / 10Hz / 100Hz / 1000Hz)、Low(10Hz / 100Hz / 1000Hz / 40kHz)

Anti aliasing filter:50~40kHz

Window function type:rectangular、Hanning、Hamming、Flat Top

Lines:Linear, peak, square root

Dynamic balance

Speed range:60~300,000RPM

Dynamic balanceSingle, double-sided dynamic balance, vibration analysis, rapid dynamic balance analysis

Acquisition signal typeThe unit can be set free

Operation:Wizard type operation

Toolboxtime/frequency domain analysis, history browsing, manually entered, data review, vector decomposition/synthetic, ISO permissible unbalance query, add calculation

Why choose us?

- Our products are backed by a satisfaction guarantee, ensuring you are happy with your purchase.

- The pursuit of excellence is the internal driving force for the progress of all kinds of work. Therefore, we should always aim to achieve first-class.

- We provide comprehensive and reliable product warranties to protect our customers.

- We insist on continuous improvement, improve performance of Portable Dynamic Balancer, and enhance its reliability and safety.

- We work closely with our customers to provide customized solutions and services.

- Our management policy is to serve with heart, manage scientifically, produce honestly and pursue better.

- Our knowledgeable team is always ready to assist with any inquiries or concerns.

- We constantly innovate in the Portable Dynamic Balancer field, continuing to exceed customer expectations, and make unremitting efforts to achieve sustainable development.

- We offer excellent value for money, making our products an affordable investment for your business.

- In terms of product development, we have always kept pace with the international frontiers and established a complete Portable Dynamic Balancer development platform and environment.

No Information

You Might Also Like

Send Inquiry